Detailed design for Lincoln University’s heating decarbonisation project

Honoris first worked with Lincoln University in 2019, looking at their energy use on campus. That study became a review of their electrical network. Then in 2021, we were invited to bid to become their detailed design partner for their campus heating upgrade.

Becoming an exemplar of sustainable practice

Lincoln University Energy Manager Daniel Brown explains why Lincoln decided to decarbonise. “Like many educational campuses in New Zealand, Lincoln University is heated by a big, old coal boiler which pipes steam around campus to warm our buildings.”

“The consent for that boiler ends in March 2025. In 2020, the university evaluated if it made sense to extend use of the boiler. Getting another consent would require millions of dollars’ worth of investment to bring the 50-year-old steam pipe infrastructure up to code. And if we spent all that money, we’d still end up with an unsustainable asset using coal.”

“Our other option was to invest a bit more money and start decarbonising the campus. One thing that guided our thinking was a growing awareness that to attract the calibre of students we want; we've got to walk the walk as well as talking the talk. As a premier land-based university, we teach, research, and showcase environmentally sustainable practices. And we should be doing all we can to be a leader in that space, and ensure we meet the goals we’ve set to be carbon neutral by 2030, carbon zero by 2050, and an exemplar of sustainable practice.”

Lincoln’s decarbonisation journey

Initially, Lincoln looked at going from a coal boiler to a biomass boiler, but that still releases emissions into the environment. So, they made the decision to electrify the campus for the future. Daniel says, “If you were building a new campus from scratch today, you wouldn't use a boiler. You’d try to do everything as efficiently as possible and given how renewable our energy grid is in New Zealand, that means using electricity.”

The university selected air source heat pumps as their heating solution. Daniel says, “Energy engineering specialist consultants created a high-level concept to define the sorts of equipment we’d need and where it should be located, but they're not design specialists, and neither are we, so that's where Honoris came into the picture.”

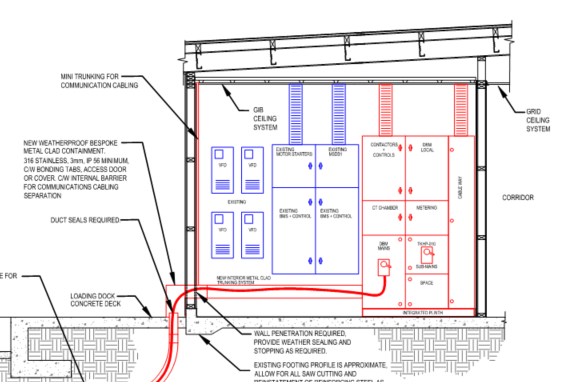

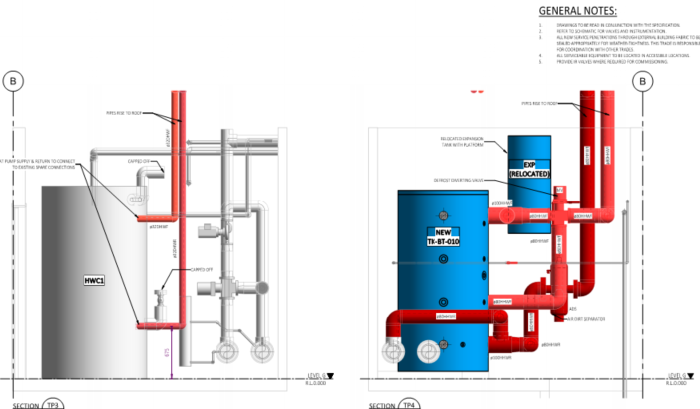

“Honoris started out by evaluating the initial concepts, creating detailed designs, and figuring out what specific pieces of equipment we need. They create a package of designs we can pass on to the delivery contractor who’ll build the new heating system.”

A complex project with many arms and legs

Stuart Taylor from OCTA Project Management is managing the heating upgrade for the university. He explains, “We tackled the campus in two phases, with each building its own project. The challenge with this upgrade was accommodating each building’s particular circumstances. Our aim was to replace the existing systems in situ, using the existing plant rooms. And so, the challenge Honoris had was to make sure their designs and the equipment they specified fit within the existing plant spaces without building new plant rooms.

“It’s a complex project because it's got so many arms and legs. The university doesn’t have an unlimited budget so Honoris have had to tailor their designs to fit, which is a challenge in the current economic environment. That has included looking for solutions locally in New Zealand and Australia, as opposed to importing plant from too far away, particularly where supply chains are constrained and lead times and costs are more challenging.”

“The biggest eye opener for me came when we were designing the placement of the new equipment. I was surprised by the size of the new equipment. It seems like, as technology advances the equipment needed for heat and ventilation gets bigger and bigger. I thought it would be the other way around. And the scale of the new plant creates a challenge when you've got small plant rooms, limited real estate on campus, and limited budgets.”

Big believers in a sustainable, whole system approach

We’ve just been re-appointed as design partners for the second phase of the campus heating upgrade, and we’re entering the delivery phase, where our designs will be installed.

Daniel says, “The designs Honoris have produced for us are practical. Their team are doing a good job communicating with Airtech who are installing the new system. I feel they’re on top of things. I don’t have to worry about whether they’ll provide the correct info. I'm confident and happy the technical design solutions they’ve provided are going to work.”

“Honoris are always friendly to deal with and clear communicators. I've always had the sense they’re big believers in this project, and keen to see it through. So, it's great having them involved from start to end. Honoris have so much embedded knowledge of this project that it's especially helpful for us to keep that IP within our team for the whole project.”

Stuart agrees. “They've done a good job. They've provided us with the designs we need. They welcomed an independent peer review to make sure their designs are robust. Honoris are a small team, but they're committed to providing you the expertise you need, they're passionate about what they're doing, and they’re keen, which has worked well for us.”

Contact us for detailed designs for your heating upgrade

Energy efficiency is at the heart of what we do because sustainable services make buildings cheaper to operate, more comfortable, and less damaging to our environment. It’s a win for everyone. So, the Lincoln decarbonisation project is right in our sweet spot.

If your heating and cooling systems are reaching the end of their life, or you’re keen to upgrade to a more sustainable system, we’re here to help. Get in touch, talk to us about your project, and we’ll tell you what we can do.

Let’s talk!

If you are interested in any of the services we offer then please do not hesitate to contact us.

Unit 7/106 Carlyle Street,

Sydenham, 8023